Non-Metal chain flights sludge scrapers

Download

Click below to download our catalogue

DWA fabricates and supplies Rectangular Non-Metal Chain Flight Sludge Scrapers for primary & secondary sludge settling tanks in sewer, wastewater, potable, and desalination treatment plants since 2004. Chain flight sludge scraper system removes bottom sludge settled by flights equipped, 3m distance each, and removes scums by scum skimmer in each settling tank. DWA applies high tensile strength and anti-corrosion plastics for all parts such as scraper chains, attachments, sprockets, flights, and wear strips, and drive chains. shafts, guide rails, and tension units are made of stainless steel 304 & 316. Chain flight sludge scraper system is the typical equipment to remove high loads of sludge in primary and secondary sludge settling tank. It provides higher sludge removal efficiency than any other scraper mechanisms. In the view of high loads of sludge removal, space of installation, power consumption, and long duration of operation, the most economical scraper system is chain flight sludge scraper system. DWA has the references for chain flight scraper systems in Finland, Turkiye, Morocco, China, Indonesia, Taiwan, Malaysia, India, Nepal, Vietnam, since 2004.

DWA has installed and run 12 units of Non-Metallic chain flights sludge scrapers in Guheswori WWTP Kathmandu Nepal successfully by 2020. 8 units for primary sludge settling tanks, 23Lx5Wx3.5Hm and 4 units for secondary sludge settling tanks, 40Lx5Wx3.5Hm.

DWA Sprockets are made of high density of polyurethane. Water absorbing rate of sprockets is less than 0.3%. The pitch of driven chain is 66.27mm and the number of tooth is 40. The pitch of main sprocket is 152.4mm with the number of tooth 12. Pitch of Idle sprocket is 152.4mm and the number of tooth is 9. Water absorbing rate of sprockets are 0.3 to 0.5%. Flight is made of GRP with more than 50% of glass fiber reinforced. Flights are produced by pultrusion process to avoid cracking during running of flight and long time duration. Mostly the flights are installed at 3m, 3,048mm, distance. Less than 0.3% of water absorbing rate for flight. Wear shoes, 12mm thickness, are assembled to each flight to prevent the abrasion offlights during running offlights on bottom of sludge settling tanks. Wearing shoes are made of high tensile of Polyurethane. Carry & return wear strips are made of UNMW Polyurethane. Thickness of wear strips are 10mm and fixed to bottom by stainless steel 304 or 316 cone washers.

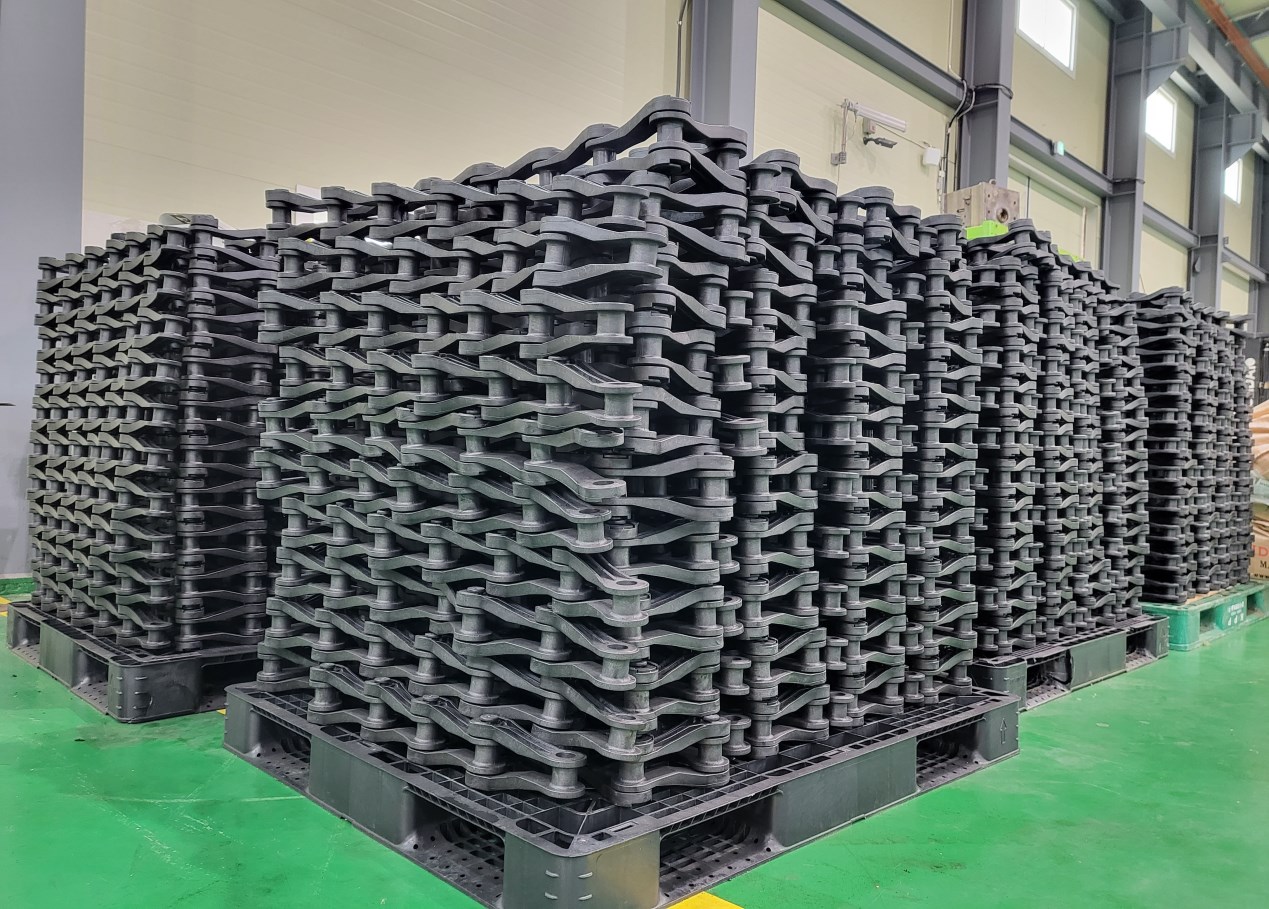

Non-Metallic Chains

DWA Non-Metallic scraper chains are made of high tensile Polyketone. Pitch of chain is 152.4mm. Tensile strength of chain is 30 to 42 kN. Has an excellent mechanical characteristics as very high anti-corrosion. Chain body, pin, and clip are made of same ma-terial and no metal parts are applied which cause disassembling of chain connections by corrosion of metal materials. Provides with attachment for chain flights. Weight is 2.4 kg per meter. Tensile strength is tested & verified by Public Testing Institutes.

DWA produce non-metal chains directly by it’s a special production line and also has the references for the supply of non-metal chains to SEA, Middle East, European, and African countries since 2008. Drive unit is consisted of motor with horizontal cycloid reduction orhelical bevel gear reducer. Power transmission is done by non-metallic drive chain, Nylon 66, 66.27 mm of pitch. Variable scraping speed control is available.

Scum Skimmer and Control panel

Advanced stainless steel scum skimmer with PLC-controlled motorized actuators and robust structure.

Dia. 250mm stainless steel scum skimmer run by motorized actuators. Each actuator has PLC system to control rotation direction and speed of scum skimmer.

Main body of scum skimmer is made of stainless pipe, 304, <t>250mm. There are 5 openings to receive and discharge scums. Scum pipe is supported at both sides to endure t wist and loop trust. Motorized actuator is run a PLC controller

Control panel is made of stainless steel 304, 2mm thickness. Automatic and manual operation by Remote/Local selector switches. Alarm and auto stop of motor by torque limit installed. Automatic stop of equipment by all fault signals and re-set are available.

Main body of scum skimmer is made of stainless pipe, 304, ø250mm. There are 5 openings to receive and discharge scums.Scum pipe is supported at both sides to endure t wist and loop trust. Motorized actuator is run a PLC controller

Control panel is made of stainless steel 304, 2mm thickness. Automatic and manual operation by Remote/Local selector switches. Alarm and auto stop of motor by torque limit installed. Automatic stop of equipment by all fault signals and re-set are available.