Travelling bridge scrapers

Download

Click below to download our catalogue

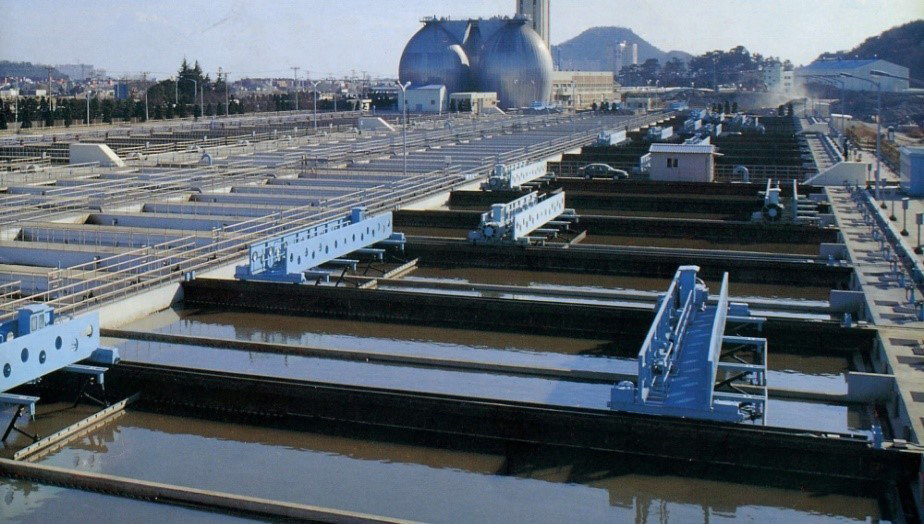

Travelling bridge scrapers are installed at a local sewer treatment plant and potable water treatment plants. Wide is 5 to 12 meters in one bridge for one water channel or one bridge for two water channels. Ideal for the scrapping of heavy-duty top and bottom sludge.

Forwarding speed of bridge is 0.2 to 1.8m/min, variable, and reverse speed is 1.8m/min, variable. Drive system will be either the drive motor with cycloid reduction or worm geared reduction type. Skimmer and scraper installed to scraper top and bottom sludge. Cable reel installed.

DWA Fabricated & supplied 20 units of chain flight sludge scrapers to a WWTP, Steel Mills in Istanbul, Turkiye in 2010. W4.8 x H4.3 x L24m, 10 units for primary sludge settling tanks and W4.8 x H4.3 x L42m, 10 units, for secondary sludge settling tanks. Scrapping speed is 0.2 ~ 0.6ml min. Shear pins protection on drive sprockets against overload of equipment.

Exception for bridge structure, all parts submersed are made of stainless steel 304 or 316. Submersed scraper is driven by stainless steel wire and drum.