automatic rotary trash bar screen

Download

Click below to download our catalogue

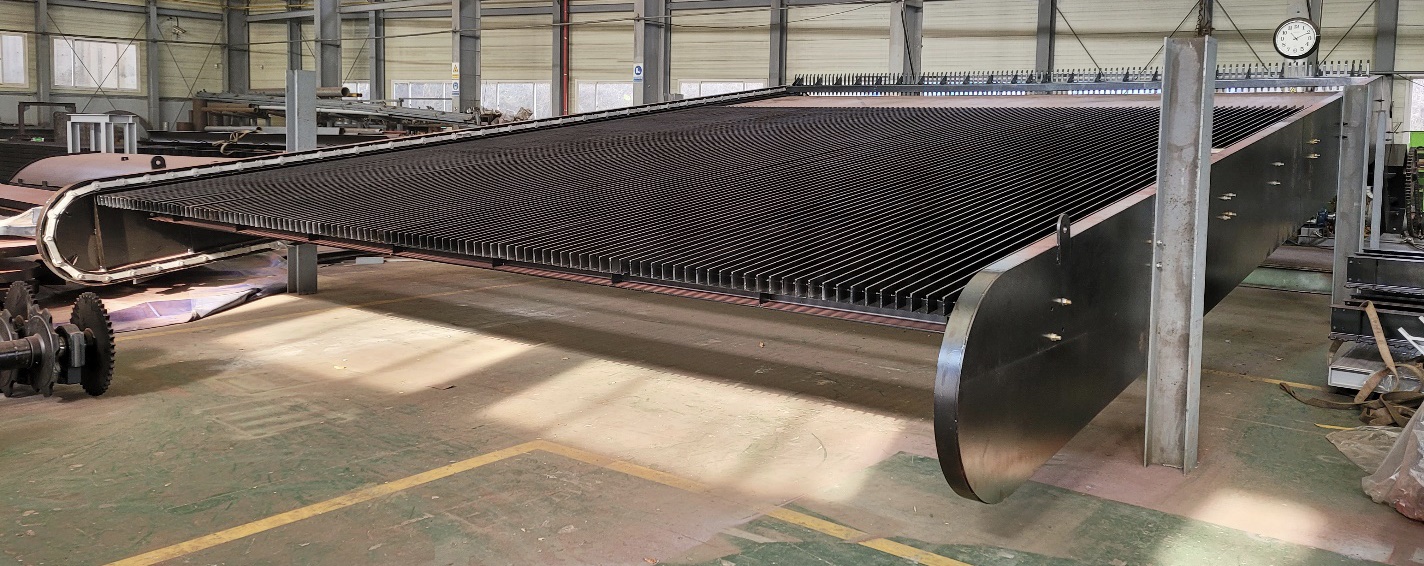

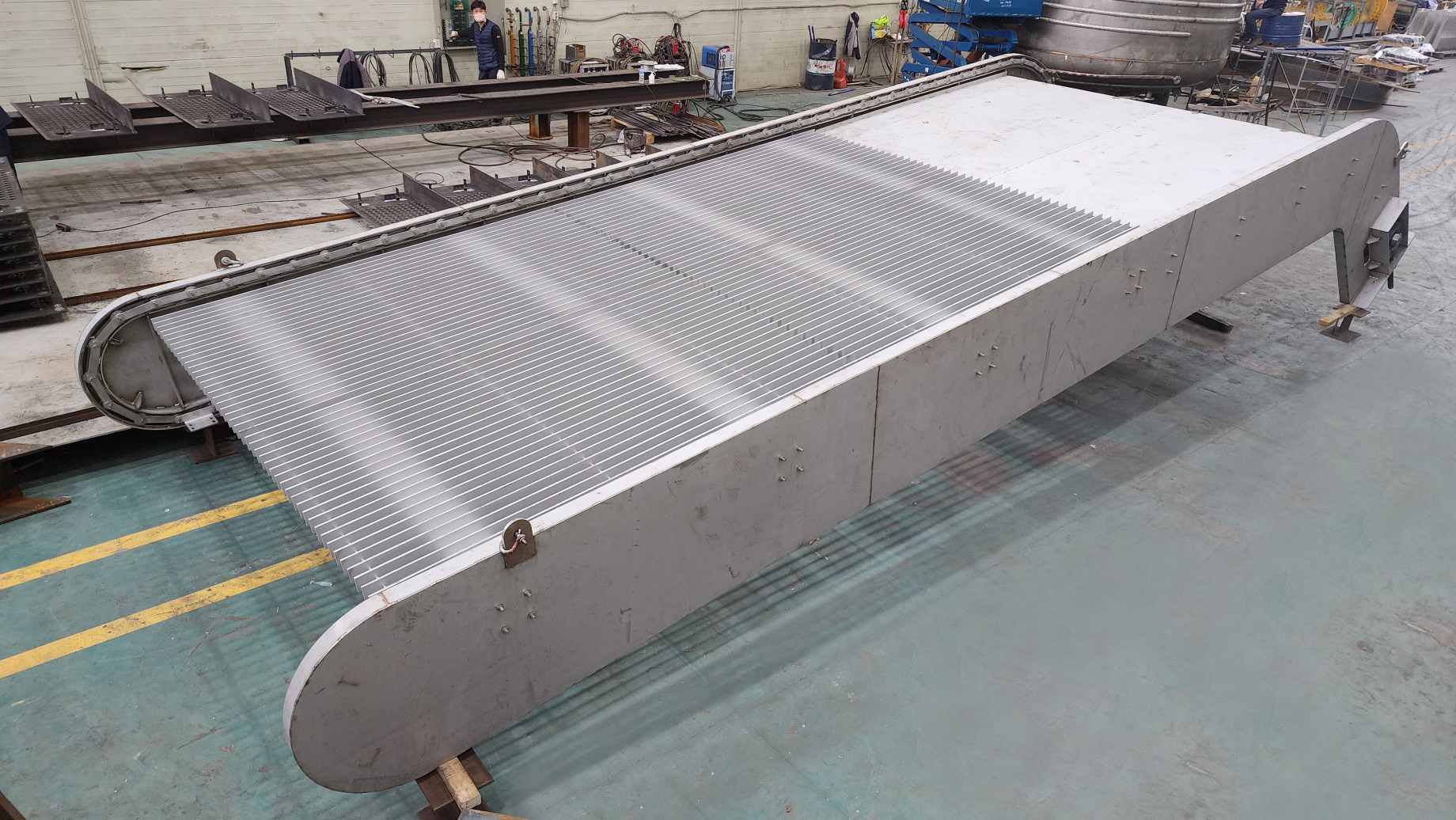

Automatic rotary bar screens are Installed on front of river water pumping stations to lift-up trashes and foreign materials automatically in river water incoming. Automatic rotary trash bar screen plants are consisted of numbers of rotary screens, horizontal belt conveyor, inclined belt conveyor, and hopper. Running of automatic rotary bar screens, belt conveyors, and hopper is automatic interactively. Rotary bar screens are mostly made of mild & carbon steel tar epoxy coated, and stainless steel 304, and 316. The opening of bar space is 50 to 60mm. Double chain system at both side are applied and the chain is made stainless steel. 4 to 5 rakes are applied typically and the speed of rake rotation is 5.0 m/min. Lifting weight for each rake is 300 to 500kg/cycle. Installation degree of rotary bar screen is 75°. Drive system is variable such as motor, hydraulic coupling, and gear box, or motor with Cycloid reducer to control smooth and long duration of run of equipment. DWA has so many references for Automatic Rotary Trash Bar Screens in South East Asian countries such as Malaysia, Thailand, Vietnam, since 2014 and has contributed to successful run of river water pumping stations for the proper water supply and flood prevention in the territory.

Automatic Rotary Trash Bar Screens has applied various dimensions and materials

DWA has directly fabricated and supplied more than 50 units of Automatic rotary trash bar screens to SEA countries since 2014. Dimensions has applied is 2 to 8m width and 5 to 12.5m of height. Materials has been applied are stainless steel 304,316 and structural steel specially coated with Epoxy Tar, according to site conditions.

Shipping picture for side frames of rotary bar screens 8m width & 12.5m height

Assembly for rake, shaft, sprocket, main chain, chain tension uint & front screen.

Assembly for main shaft, sprocket, rake, main chain, and chain tension units. All parts are assembled in precise and allowed dimensions under DWA ‘s dedicated quality control system.

DWA has a special design for trash rakes to lift up trash well. Main shafts are made of carbon steel tar epoxy coated in enough thickness.

Drive system is consisted of Induction motor, hydraulic coupling, & high ratio of gear reducer.

DWA Drive system for automatic rotary bar screens is Gear box with hydraulic coupling or Cycloid reducer for smooth start up and running of equipment. 2.2 to 5.5kw, IP55, motors are applied. Shear pins protection for overload.