Mechanical bar screens

Download

Click below to download our catalogue

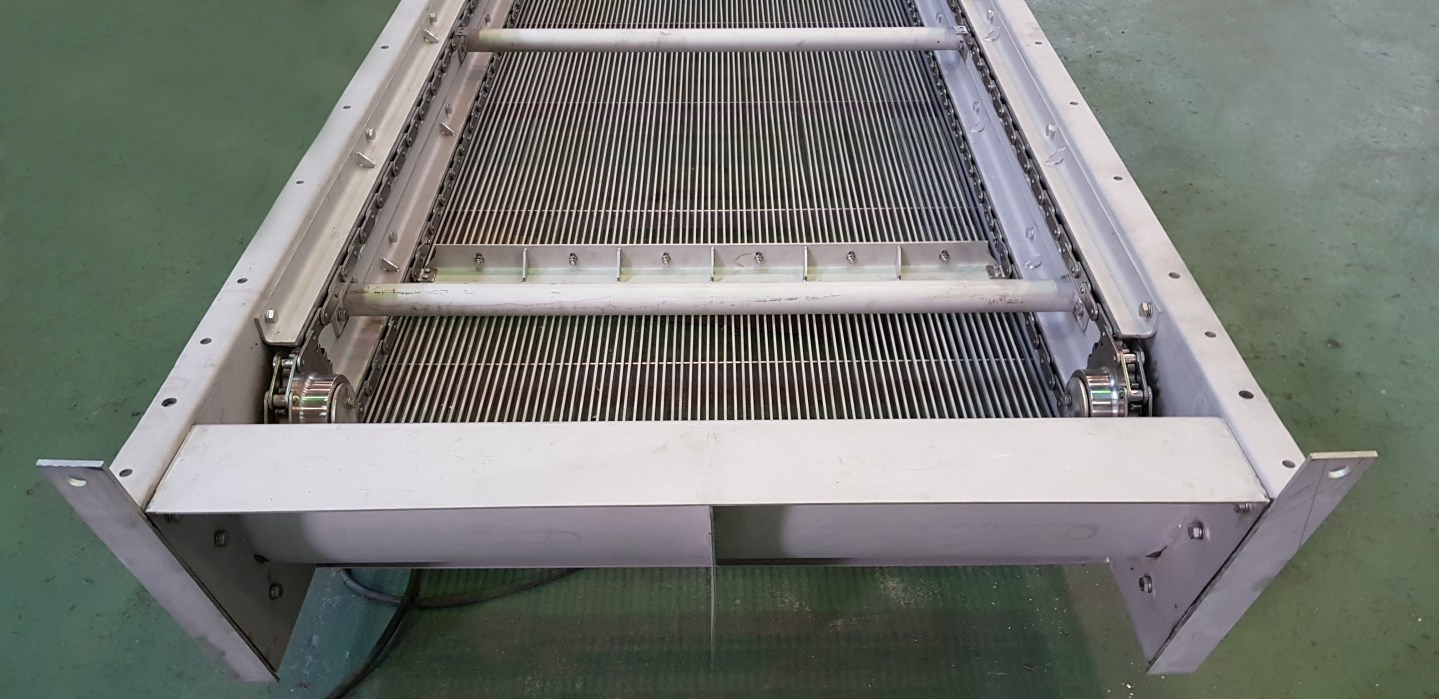

DWA fabricates & supplies Automatic coarse & fine mechanical bar screens, double chain rakes rotation type, for grit chamber and raw sludge water incoming stations. All equipment are made of stainless steel 304, 316, or Duplex stainless steel. Main chain for rake rotation is also made of stainless steel. For the rake cleaning before discharge of sludge to chute, a sludge scraper is installed on the top & rear side of screen equipment. Installation inclination is 60. to 75°. Bar clearance is 20 to 25mm for coarse mechanical bar screens and 6 to 10mm for fine mechanical bar screens. Typical raking speed is 3m/ min. which is adjustable according to customer request. An wedge bar system will be applied to fine screen to avoid clogging of screenings passing through. 10 to 14 numbers of rakes are equipped in mechanical bar screens and there are 2 sprockets, top & bottom parts, to run rakes and chains. Bottom sprocket areremoveable according to specification. Shear pin protection devices are equipped on drive sprocket to protect equipment against overloads. Drive system is Cycloid reducer or Geared motor reducer. Control panels for automatic, manual runs, are also supplied byDWA.

DWA has supplied Mechanical Coarse and Fine bar screens to SEA countries and US military in Korea since 2010.

Mechanical fine bar screen installed Bangkok Thailand 2019. 10mm bar clearance and wedge bars equipped to avoid clogging of bar space.

4 Mechanical Coarse & Fine Bar Screens shipped to a WWTP in Vietnam 25mm bar

10mm bar clearance of fine bar screens with wedge bars to avoid clogging of bar space. Made of stainless steel 304 applied. W700 x H3,500mm Coarse mechanical bar screen installed in a US Army. Explosion proof motor and control panel applied. Made of stainless steel 316.